At Carpenter Additive, we're your all-in-one partner for metal additive manufacturing (AM). With a century of expertise in precision engineering, our team pioneers the scaling of AM for qualified production in critical industries. From concept to realization, we guide you through the AM journey, offering standard and custom powders, strategic material handling, and consultative development services. Elevate your additive manufacturing with Carpenter. Additive

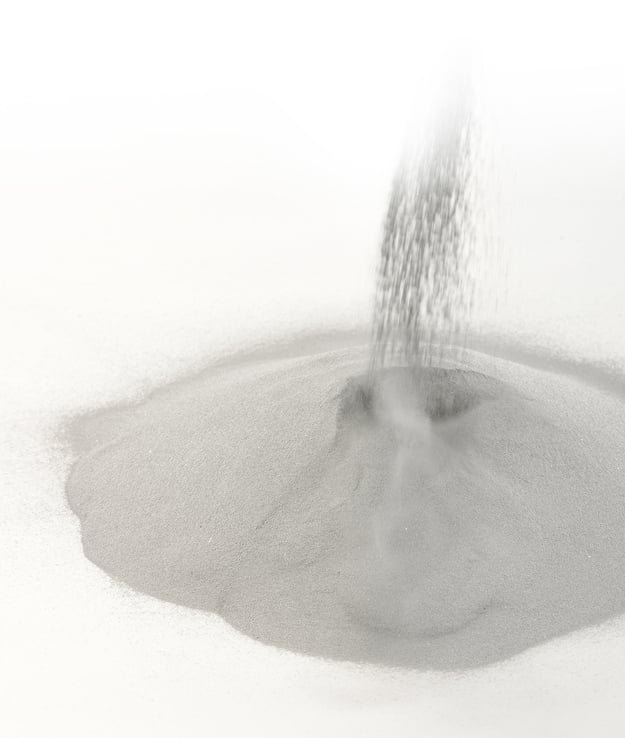

Extensive selection of off-the-shelf and custom alloy powders for metal additive manufacturing.

Quality metal powder, optimized for additive manufacturing available from a sustainable partner with rapid turnaround.

Industry-leading additive manufacturing raw material lifecycle management.

A closed-loop powder solution, from the point of atomization to loading your AM machines.

Unlock the potential of Carpenter Technology's 130-year legacy in materials expertise. Tailor bespoke alloy solutions for additive manufacturing with our adept team at Carpenter Additive. From in-house alloy development to atomization, we collaborate closely to create cutting-edge metal alloys. Whether for surgical instruments or aerospace gears, trust us as your partners in advancing additive manufacturing

1735 Market Street,

15th Floor

Philadelphia, PA 19103

United States

Carpenter Additive Liverpool

Dennis Road

Widnes

Cheshire WA8 0GU

United Kingdom

Carpenter Additive Athens

22110 Thomas L. Hammons Rd.

P.O. Box 219

Tanner, AL 35671

United States

Carpenter Powder Products AB

P.O. Box 24

SE-63102

Eskilstuna

Sweden

LPW SOUTH EUROPE

Via Nibbia 1

28060 San Pietro Mosezzo

(NO)

Italy

Carpenter Additive Japan

2F MK Higashishinagawa Bld.,

4-9-26, Higashishinagawa,

Shinagawa-ku, Tokyo,

1400002 Japan

Rehov Ha Barzel Street #3

Ramat Ha Hachayal

Tel-Aviv, 6971005

Israel

M G SALES CORPORATION

401,402 Block –A, Supath – II, Opp. Old Wadaj Bus Stop,

Ashram Road,

Ahmedabad – 380013[Gujarat]

India

Contact : Mr Hiren Parmar – Director

T: +91-9327553360

E: hiren@mgsales.net

MASCHINE TECHNOLOGY PTE LTD

Number 1399, Road 4,

Longquanyi District,

Chengdu City,

Sichuan Province,

China

Contact: Mathew Lwee

T: +65 9139 5173

E: mathew@maschinetech.com

W: www.maschinetech.com

MASCHINE TECHNOLOGY PTE LTD

449 Tagore Industrial Avenue #03-02

Greatland Industrial Building,

Singapour 787820

Singapore

Contact : Dr Keng-Pang Lim

T : 0065 9139 5173

E : sales@xsecpro.biz

AM SOLUTIONS

A312, Indeokwon IT valley,

40 Imiro, Uiwang-city,

Gyeonggido, 437-120 Korea

Contact: Mr. Dongsik Kim

T: 82-10-6202-8405

E: dskim@amsolutions.co.kr