Discussing a Novel Titanium Solution for the Additive Manufacturing of Medical Devices

During this webinar, Gaurav Lalwani, Ph.D., Medical Applications Development Engineer, and Ken Davis, Director of Additive Technology, discuss Ti64 Grade 23+, an additive manufacturing solution that combines controlled powder chemistry with lower oxygen content and optimized print parameters and examine builds delivering a 15-20% improvement in mechanical properties and consistent, high-quality results.

About Carpenter Additive

Combining more than a hundred years of metallurgical leadership with unrivaled knowledge of additive manufacturing technologies, Carpenter Additive is committed to helping customers solve material and process challenges. Developing end-to-end solutions to add consistency, reduce risk, and continuously improve additive manufacturing production, Carpenter Additive offers high quality metal powder, a suite of solutions for material traceability, and contract manufacturing from powder to part.

Novel Titanium Optimized for Additive

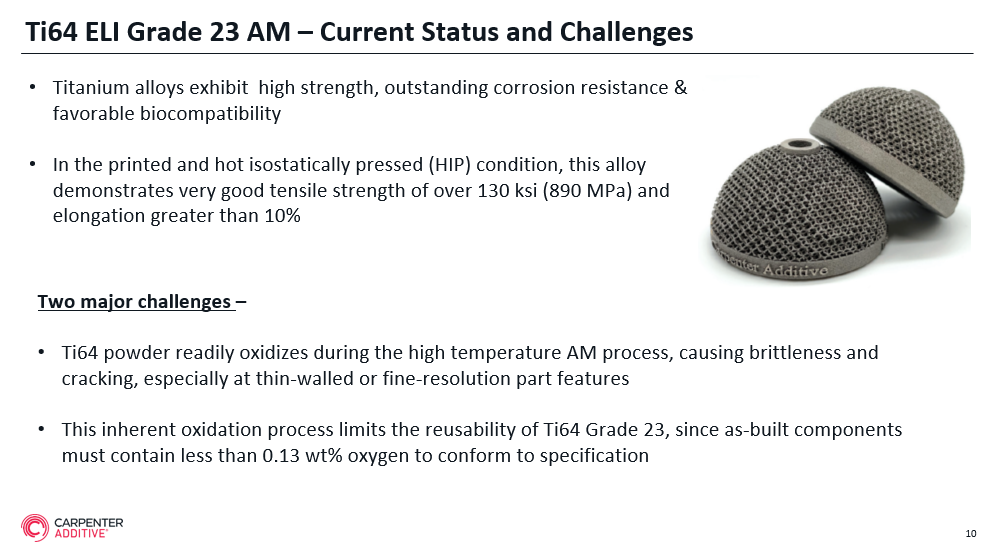

In order to achieve complex geometries with Ti64, Carpenter Additive’s material experts developed an integrated printing solution to control the entire additive lifecycle — from powder chemistry to additive build parameters to the recycling process.

Ti64 ELI Grade 23+ allows 3D printing of complex, high-quality medical devices with increased mechanical strength and improved ductility.

Learn More About Our Portfolio of Innovative Solutions

-

PowderRange

Off-the-shelf and custom metal powders

-

PowderLife

Powder management solutions for material traceability

-

Manufacturing Services

End-to-end additive production