AM POWDER MANAGEMENT

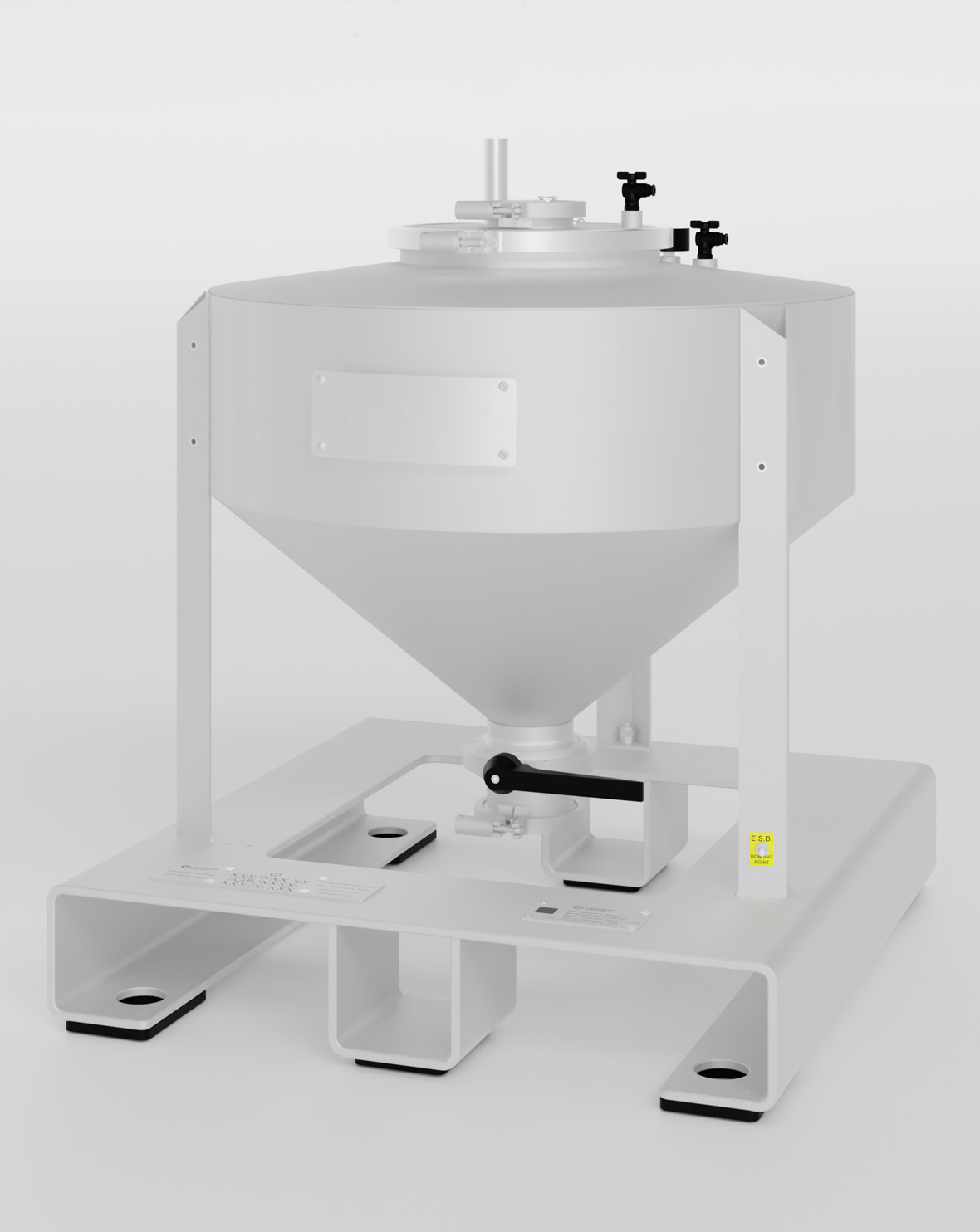

Carpenter Additive’s sustainable 120 L stainless steel hopper for additive manufacturing offers a bulk supply of premium metal powder.

Bulk powder handling for additive manufacturing

Carpenter Additive is the world’s leading supplier of metal powders optimized for AM — and the first AM-focused materials company to engineer sustainable, production-ready powder delivery solutions. The 120 L Hopper gives you a bulk supply of the high-quality powder you need in an easy-to-transport, easy-to-store form.

- Boost volume: Up to 400 kg of powder per 120 L Hopper

- Minimize waste: One Hopper replaces tens of non-recyclable plastic bottles

- Improve safety and quality: Minimize operator exposure and contamination while optimizing operational efficiency and traceability

Scaling up AM production

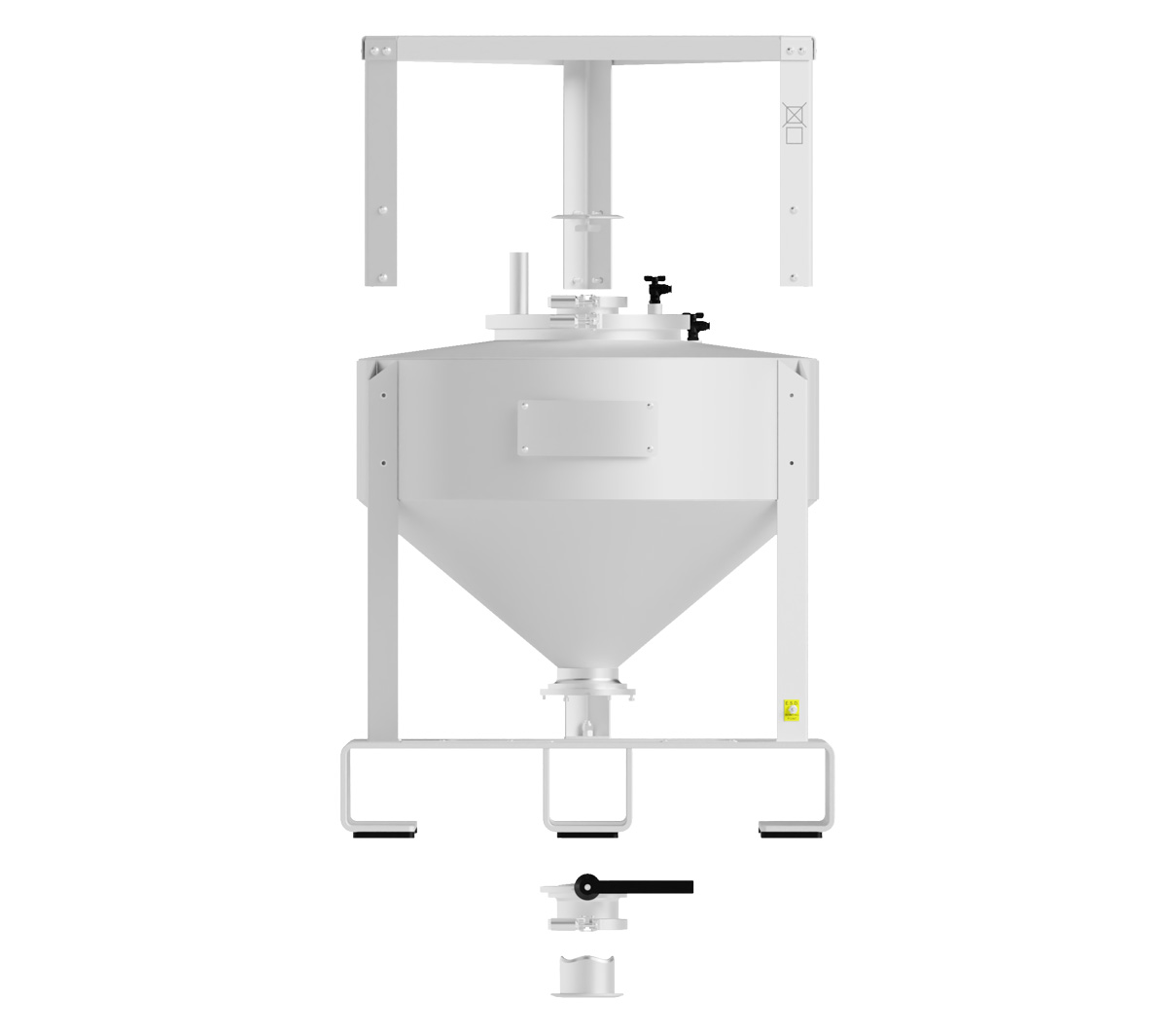

The 120 L Hopper is engineered for smaller AM sites and closed-loop system compatibility. For larger AM sites, new AM systems, and larger capacity and transport security, ask about our new 250 and 500 L Hoppers.

Hopper 120 L |

|

Max. fill 400 kg / 881 lb |

|

Size 810 x 965 x 865 mm |

Hopper 250 L |

|

Max. fill 1000 kg / 2204 lb |

|

Size 915 x 1220 x 915 mm |

Built to perform

The Carpenter Additive 120 L Hopper provides a closed-loop powder solution, from the point of atomization to loading your AM machines. Metal powders for 3D printing are transported and stored under inert conditions when required, minimizing the risks of operator exposure and material contamination. Each 120 L Hopper can be customized to identify the specific alloy contained within and is clearly labelled for easy traceability.

- Push-fit connection points to maintain inert atmosphere

- Valves engineered to prevent powder escape

- Patented valve blocker to keep powder inside during transport

- Material identification and serialization plates

Built to move

The Hopper is UN-certified for the transport of hazardous goods and offers 2-way access for pallet, pedestrian, and forklift equipment.

Built to sustain

Filling a high-volume machine with small containers of powder is inefficient and wasteful. Easy to use and easy to clean, the 120 L Hopper is a reusable, recyclable powder supply solution that, with each full fill, contributes to saving approximately 17 kg of plastic waste on average. The Hopper can help you achieve both your production-scale AM and sustainability goals.

For even greater storage and capabilities, ask about our 250 and 500 L Hoppers for production-scale AM.

SUPERIOR METAL POWDER FOR 3D PRINTING

The powder to power additive manufacturing is in the Hopper. Turn to Carpenter Additive’s broad portfolio of high-performance alloys.

Powder up with Carpenter Additive