Related Resources

Browse our technical library of resources, inlcuding: white papers, product brochures, technical datasheets, webinars, and more.

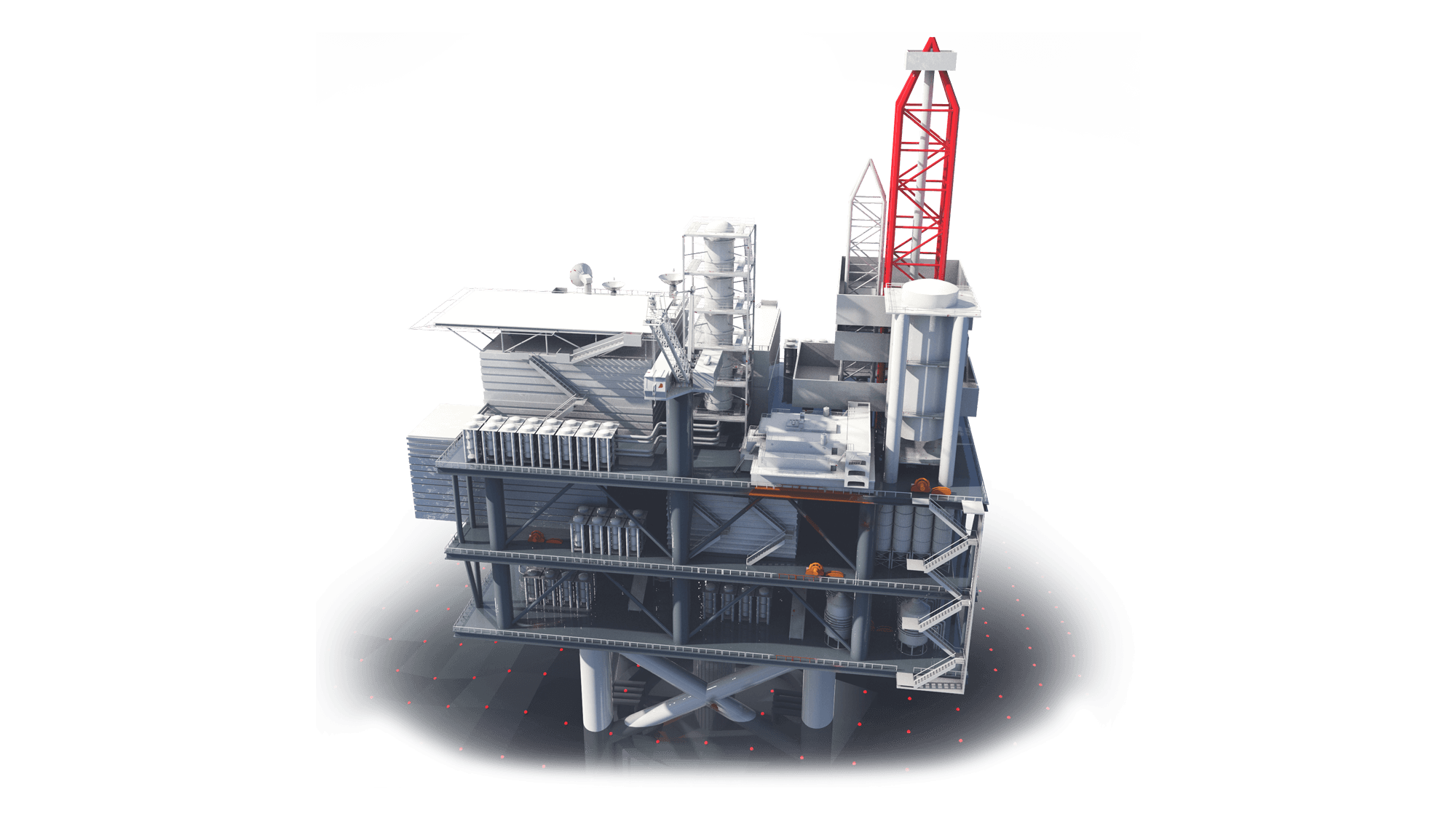

Developing natural resources such as oil and gas, and generating energy through combustion, nuclear, and renewable methods require advanced alloy materials the possess tremendous levels of performance and reliability. The team at Carpenter Additive understands these challenges and partners with customers to innovate and produce additive solutions with increased functionality, reduced costs, and a decreased time-to-market.

Whether wear-resistance, corrosion-resistance or high-temperature, Carpenter Additive’s experts can help identify the right material to optimize performance and move customers to production of highly functional components ready for end-use, all in-house.

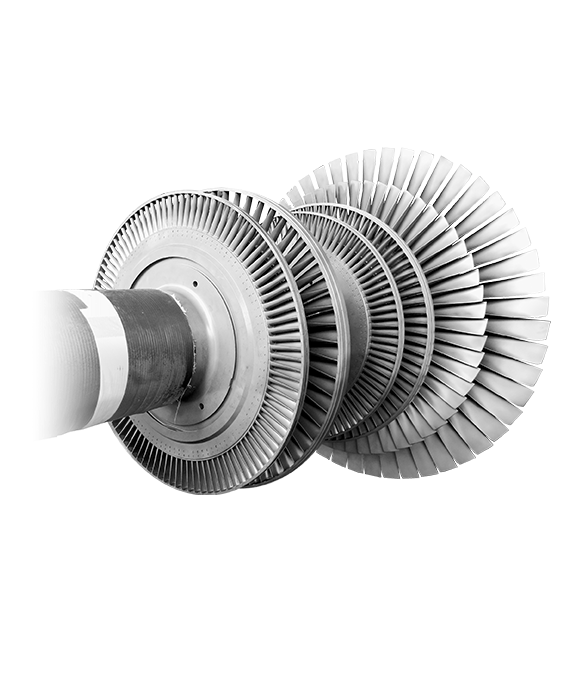

Readily fabricated, crack-free turbine blades additively manufactured in a range of superalloys with elevated temperature stability. These alloys are designed for hot gas path components to take advantage of 3D design freedom which can improve turbine efficiency by leveraging advanced cooling airflow architecture.

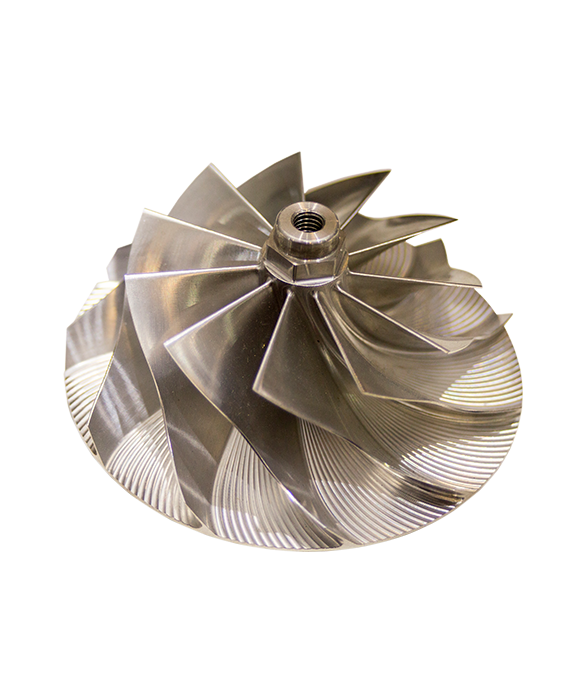

AM impellers can offer improvements to both mechanical properties and manufacturing lead times compared to cast parts. Shortened lead times reduce downtime and improve the efficiency of inventory management programs.

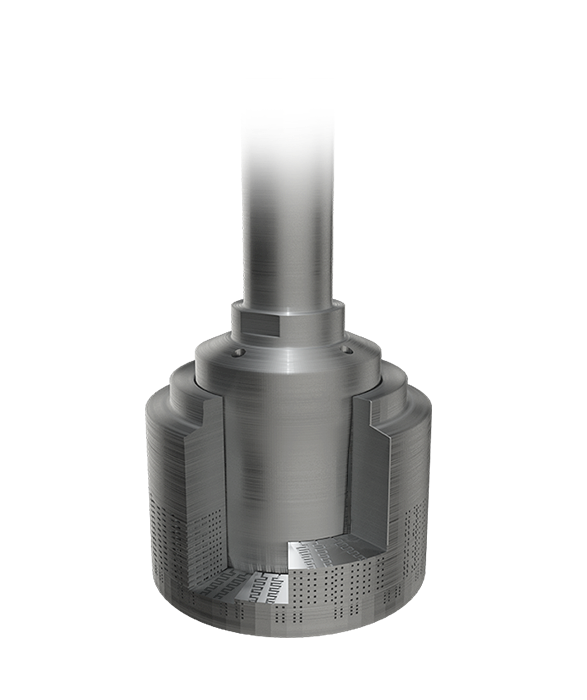

Complex valve trim is utilized to regulate pressure changes across the valve and minimize sound pressure levels. Traditional fabrication techniques often involve welding together many plates, each milled with a complex flow channel. AM parts simplify the assembly and eliminate the need for multiple welds.

RSS contain complex components like pressure manifolds that benefit from the design flexibility afforded by additive manufacturing. AM parts offer increased performance compared to traditional casting techniques.

Optimized air-fuel mixing is critical to efficient combustion. Additively manufactured parts enable a more uniform distribution of atomized fuel within the combustion chamber and complex assemblies are simplified.

Customers call on us when they need to rethink the boundaries of specialty alloys or how our existing top-performance materials can solve new design challenges. We foster long-term relationships to support risk-adverse innovation and explore advanced product applications together

Customers call on us when they need to rethink the boundaries of specialty alloys

Browse our technical library of resources, inlcuding: white papers, product brochures, technical datasheets, webinars, and more.