Applicable specifications:

AMS5659

Associated specifications:

UNS S15500, ASTM A564/A564M, AMS7021

Single figures are nominal except where noted.

| Iron |

| Copper |

| Molybdenum |

| Carbon |

| Sulfur |

| Balance |

| 2.50–4.50 % |

| 0.50 % |

| 0.070 % |

| 0.015 % |

| Chromium |

| Manganese |

| Niobium |

| Oxygen |

| 14.00–15.50 % |

| 1.00 % |

| 5x C to 0.45 % |

| 0.030 % |

| Nickel |

| Silicon |

| Nitrogen |

| Phosphorus |

| 3.50–5.50 % |

| 1.00 % |

| 0.10 % |

| 0.030 % |

PowderRange® 15-5PH stainless steel is a martensitic precipitation/age-hardening stainless-steel similar to 17-4PH offering higher strength and hardness, along with excellent corrosion resistance, up to 600°F (316°C). It has good fabricating characteristics and can be age-hardened using a single-step, low temperature treatment that can be chosen to achieve specific strength and toughness combinations. Due to this balanced combination of performance and ease of use in AM, 15-5PH stainless steel has been used for a wide variety of additive manufacturing applications, including rapid tooling, functional components in nearly every market, and prototyping.

| Part Number | PowderRange® 155 F |

|---|---|

| Application | L-PBF1 |

| Maximum Particle Size | Max 1 wt% > 53 µm2 |

| Minimum Particle Size | Max 10 vol% < 15 µm3 |

| LSD Percentile | D10, D50, D903, reported |

| Atomization | Nitrogen Gas Atomized |

| Apparent Density (G/CM3) | Measured according to ASTM B2124 and reported |

| Hall Flow (S/50G) | Measured according to ASTM B2135 and reported |

1ASTM/ISO 52900: Laser—Powder Bed Fusion (L-PBF), Electron-Beam Powder Bed Fusion (EB-PBF), Directed Energy Deposition (DED)

2ASTM B214 Standard Test Method for Sieve Analysis for Metal Powders

3 ASTM B822 Standard Test Method for Particle Size Distribution of Metal Powders and Related Compounds by Light Scattering

4 ASTM B212 Standard Test Method for Apparent Density of Free-Flowing Metal Powders Using the Hall Flowmeter Funnel

5 ASTM B213 Standard Test Method for Flow Rate of Metal Powders Using the Hall Flowmeter Funnel

Testing of powder will fulfill certification requirements to Nadcap Materials Testing and ISO/IEC 17025 Chemical, per relevant ASTM procedures

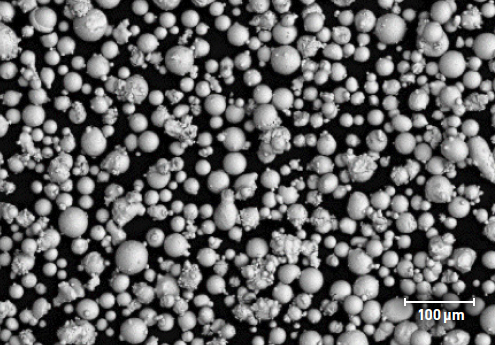

FIGURE 1—SEM IMAGE OF TYPICAL PowderRange 15-5PH POWDER

ASTM/ISO 52900: LASER-POWDER BED FUSION (L-PBF)

PowderRange 15-5PH is compatible with all commercially available L-PBF equipment.

To achieve mean, as-built density >99.9%, 20 to 60 µm layer thicknesses and Specific Energy ≥ 50 J/mm3 is recommended.

Stress relieve at 1250°F (677°C) for 1 hour per inch of thickness (minimum 2 hours) up to 4 hours.

Carpenter Additive recommends a homogenization treatment at 2000°F (1093°C) for 1 hour followed by an air cool to minimize anisotropy. If performing a HIP step, a separate homogenization treatment is not required.

PowderRange 15-5PH is readily machined in both the solution-treated and various age-hardened conditions. In the solution-treated condition, it machines similarly to stainless steel types 302 and 304.

When using carbide tools, surface speed feet/minute (SFPM) can be increased between 2 and 3 times over the high-speed suggestions. Feeds can be increased between 50 and 100%.

TYPICAL MICROSTRUCTURES

| Condition | TRANSVERSE (X-Y PLANE) | LONGITUDINAL (Y-Z PLANE) | NOTES |

|---|---|---|---|

| As-Built |

|

|

Mean densities greater than 99.9% |

HIP/Sol/Age

|

|

|

Up to 100% density |

| As-built, etched6 |

|

|

Typical pre-solutionized PowderRange 15-5PH microstructure, consisting of martensite with minimal carbide precipitates |

| Hom/Sol/ H900, etched6 |

|

|

Average grain size ASTM 7-87 Typical PowderRange 15-5PH aged martensitic microstructure |

| HIP/Sol/ H900, etched6 |

|

|

Average grain size ASTM 7-87 Typical PowderRange 15-5PH aged martensitic microstructure |

6 Etched with Ralph’s etchant

7 ASTM E112 Standard Test Method for Determining Average Grain Size

IMPORTANT NOTE: The following 4-level rating scale (Excellent, Good, Moderate, Restricted) is intended for comparative purposes only and is derived from experiences with wrought product. Additive manufactured material may perform differently; corrosion testing is recommended. Factors that affect corrosion resistance include temperature, concentration, pH, impurities, aeration, velocity, crevices, deposits, metallurgical condition, stress, surface finish, and dissimilar metal contact.

IMPORTANT NOTE: The following 4-level rating scale (Excellent, Good, Moderate, Restricted) is intended for comparative purposes only and is derived from experiences with wrought product. Additive manufactured material may perform differently; corrosion testing is recommended. Factors that affect corrosion resistance include temperature, concentration, pH, impurities, aeration, velocity, crevices, deposits, metallurgical condition, stress, surface finish, and dissimilar metal contact.

| Nitric Acid | Good |

| Phosphoric Acid | Restricted |

| Sodium Hydoxide | Restricted |

| Sea Water | Excellent |

| Humidity | Moderate |

| Sulfuric Acid | Moderate |

| Acetic Acid | Good |

| Salt Spray (NaCl) | Restricted |

| Sour Oil/Gas |

| Company |

| Other Generic Names |

| Concept Laser |

| EOS |

| DMG Mori (Realizer) |

| Renishaw |

| SLM Solutions |

| Alternative Title |

| 1.4540, 15-5PH |

| - |

| PH1 |

| – |

| – |

| 1.4545 (15-5PH) |

For additional information,

please contact your nearest sales office:

info@carpenteradditive.com | 610 208 2000

The mechanical and physical properties of any additively-manufactured material are strongly dependent on the processing conditions used to produce the final part. Significantly differing properties can be obtained by utilizing different equipment, different process parameters, different build rates and different geometries. The properties listed are intended as a guide only and should not be used as design data.

The information and data presented herein are typical or average values and are not a guarantee of maximum or minimum values. Applications specifically suggested for material described herein are made solely for the purpose of illustration to enable the reader to make his/her own evaluation and are not intended as warranties, either express or implied, of fitness for these or other purposes. There is no representation that the recipient of this literature will receive updated editions as they become available.

Unless otherwise specified, registered trademarks are property of CRS Holdings Inc., a subsidiary of Carpenter Technology Corporation.