Powder Equivalency

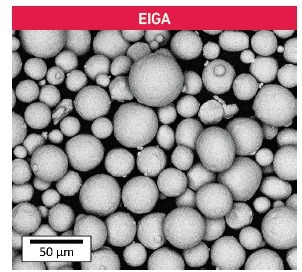

The whitepaper results support the key conclusion that EIGA and PA Ti64 powders for additive manufacturing are statistically equivalent along several quantitative measures, including oxygen level, contamination, density, flowability, and morphology.

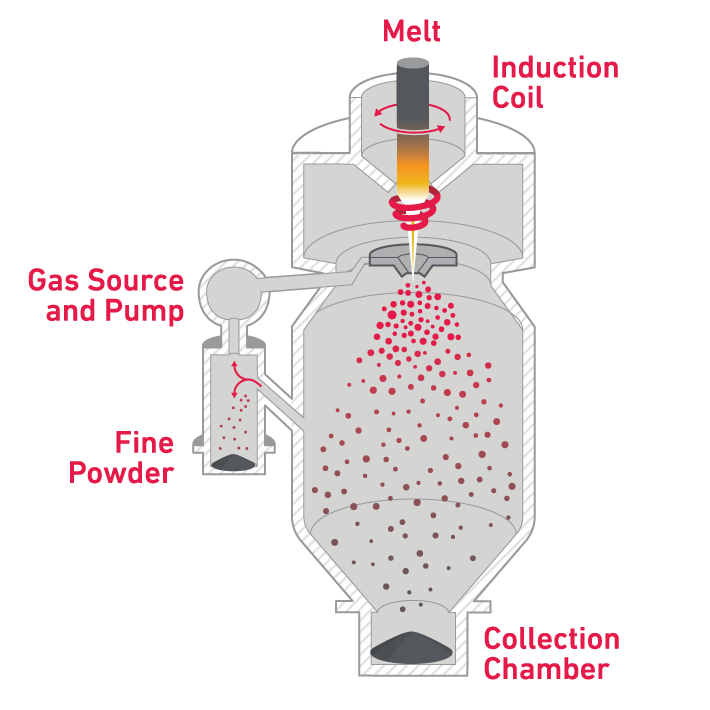

Electrode Inert Gas Atomization (EIGA) continuously melts a pre-alloyed Ti64 rod in an induction coil that falls into a gas nozzle to produce highly spherical powder particles. EIGA powder serves as an alternative to plasma atomized powder, using more economical bar feedstock.

The absence of any refractory components

in the EIGA process minimizes the risk of

high-density contaminants. The EIGA supply chain includes less feedstock processing, resulting in lower oxygen levels.

Measured through helium pycnometry, the true density test results demonstrate that powder from the two melt methods are equivalent in terms of internal porosity.

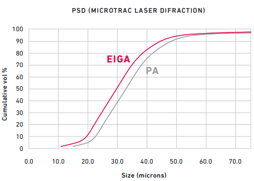

Flowability tests provide quantitative measurements of powder movement and are the most robust methods available to predict a material’s behavior during build jobs. Test results demonstrate the EIGA sample having superior flowability in a testing environment similar to a L-PBF AM machine, despite having a finer PSD.

About Carpenter Additive

Combining more than a hundred years of metallurgical leadership with unrivaled knowledge of additive manufacturing technologies, Carpenter Additive is committed to helping customers solve material and process challenges. Developing end-to-end solutions to add consistency, reduce risk, and continuously improve additive manufacturing production, Carpenter Additive offers high quality metal powder, a suite of solutions for material traceability, and contract manufacturing from powder to part.

Powder Degradation Webinar

AM users are raising quality control questions about the quality of powder and its ability to be reused for future builds. Carpenter Additive carried out a powder degradation study to investigate the oxygen content of various grades of titanium alloy (Ti64) powder during selective laser melting and material reprocessing against ASTM B348 standards, including the effects of powder blending and “topping up” strategies. Join the metallurgical and additive manufacturing experts from Carpenter Additive for this webinar exploring the results of the study.

Learn More About Our Portfolio of Innovative Solutions

-

PowderRange

Off-the-shelf and custom metal powders

-

PowderLife

Powder management solutions for material traceability

-

Manufacturing Services

End-to-end additive production