PIXL Mars Rover - Precision Additive Manufacturing for Mission-Critical Performance

| 4 min read

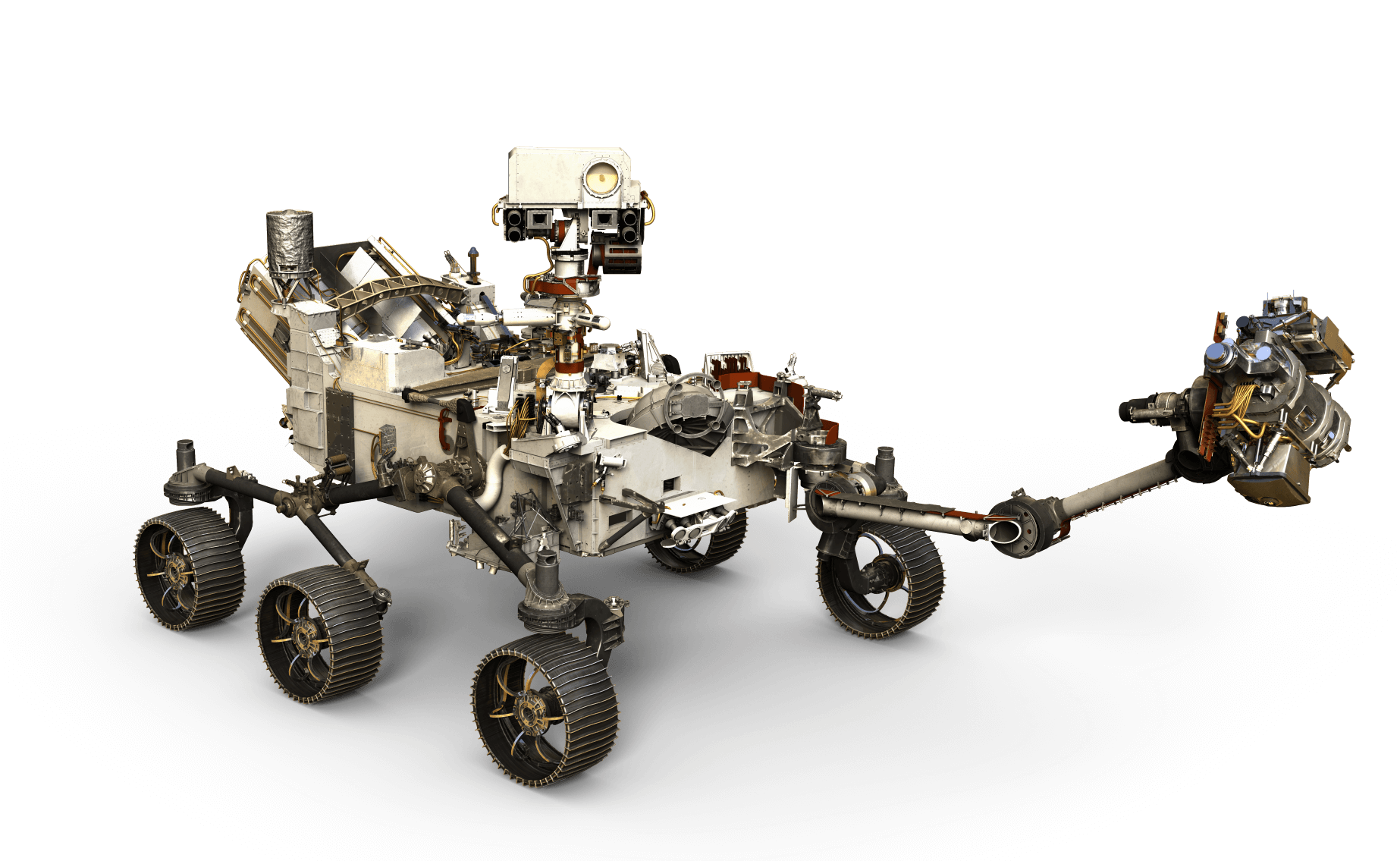

292.5 million miles. That’s how far the Perseverance Mars Rover will have traveled by the time it lands on the surface of the red planet on February 18th. The mission of the journey is to help advance NASA's exploration of the habitability of Mars by searching for signs of ancient microbial life. The Planetary Instrument for X-ray Lithochemistry (PIXL) carries a highly sensitive X-ray spectrometer for precision chemical analysis and experiments. NASA’s Jet Propulsion Laboratory reached out to the experts at Carpenter Additive to 3D print the housing for this equipment for the journey.

“Touching down on Mars can best be described as a highly engineered, controlled crash landing, and these parts have to withstand that force and then carry out precision experiments” stated Carpenter Additive's Director of Additive Technology and project lead. Despite the high-strength requirements, the team had to work with a strict mass budget, or absolute maximum weight, to ensure the component would be able to launch. Designed solely for function, the PIXL components were the most challenging Carpenter Additive had encountered with strict parameters meaning the part could not be redesigned and tolerances could not be opened.

The established manufacturing plan was a complex combination of additive and subtractive production techniques with many scanning inspections to ensure quality at every step of the process. The expert understanding of each step of the process was essential to the successful construction despite the many challenges along the way.

At completion, a total of .077 oz (22 g) was added to the 16 lb (7.26 kg) construction, within the margins to improve manufacturability. High precision Additive parts with very precise, fine machined details with 0.005 in. (0.127 mm) true position tolerances and a surface finish of 32μin Ra were achieved while the inspected mechanical properties provided greater than 130 ksi tensile strength at 15%+ elongation. On February 18th, 2021, these components will arrive on Mars to support mission critical, pioneering measurements of the chemical makeup of our neighboring red planet.

Can't get enough of Mars? Watch The Cool Parts Show #23 to learn more about the Perseverance parts made through additive manufacturing.