Related Resources

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.

Carpenter Additive provides advanced solutions and a trusted partnership to tackle your most vexing industry challenges

Carpenter Technology has over 130 years of metallurgical experience supporting mission-critical components in a range of industries. Carpenter Additive capitalizes on this history to provide an impressive range of high-quality metal powders and alloys developed specifically for industrial 3D printing processes. Our deep understanding of developing never-fail components in partnership with customers allows us to partner with customers to optimize their internal processes and expand their production at our manufacturing facilities.

Medical

Medical Carpenter Additive’s specialty alloys, stainless steels, and titanium materials have been trusted by the healthcare industry for decades. Whether 17-4 PH for medical instrumentation, Nitinol for shape memory properties in medical devices, or Grade 23+ Titanium for high-strength implants, Carpenter Additive has a portfolio of materials to accelerate product development that meet the extremely stringent composition, fabrication, and functional standards for biomedical equipment.

We continue to make advancements in high-quality iron, nickel, cobalt, and titanium-based aerospace alloys to optimize additively manufactured parts. A trusted material supplier to the world’s foremost leaders in the aerospace market, Carpenter Additive aligns material solutions and production expertise with the current and future needs of commercial and defense aviation, manned aircraft, and unmanned systems.

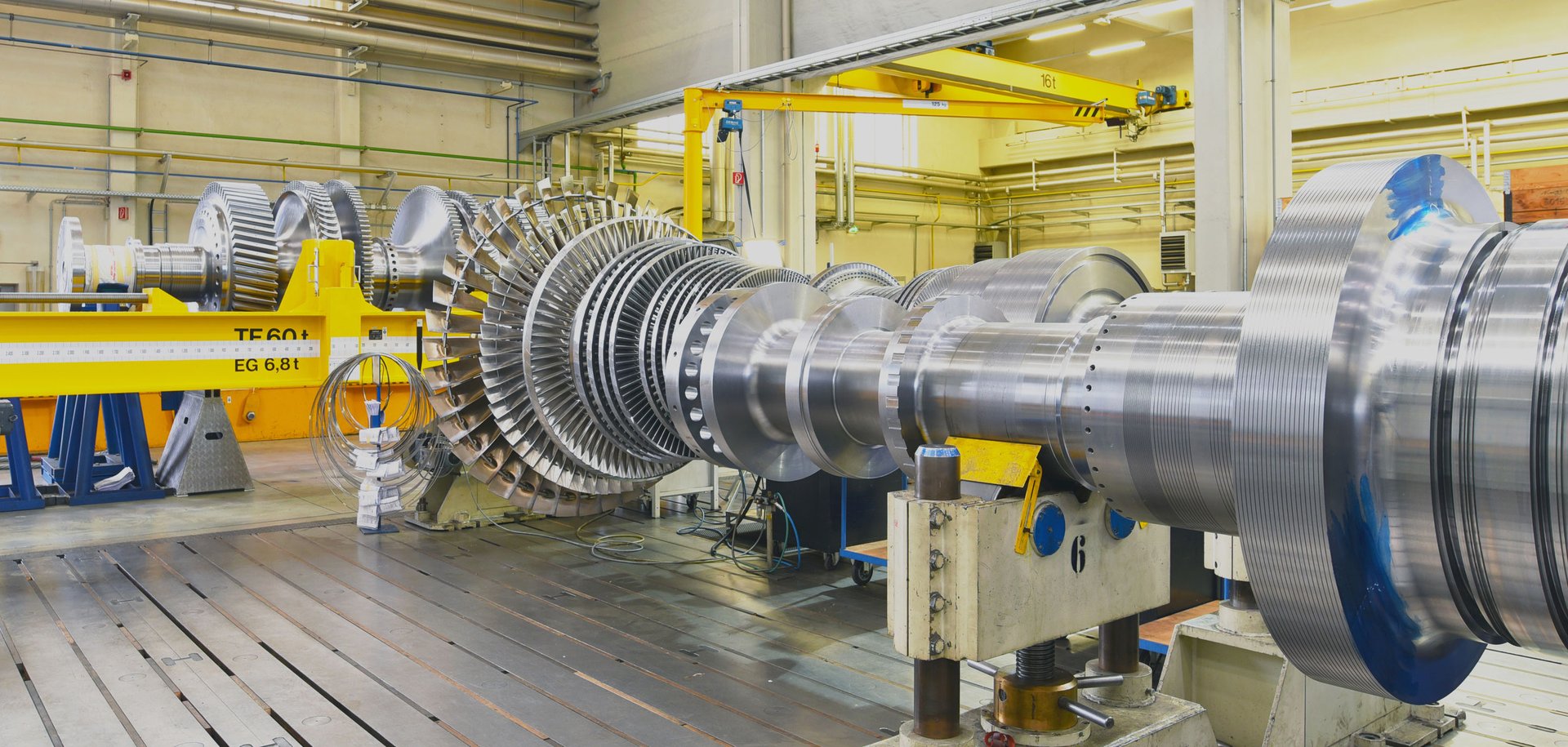

Whether wear-resistance, corrosion-resistance or high-temperature, Carpenter Additive’s experts can help identify the right material to optimize performance and move customers to production of highly functional components ready for end-use, all in-house.

Whether wear-resistance, corrosion-resistance or high-temperature, Carpenter Additive’s experts can help identify the right material to optimize performance and move customers to production of highly functional components ready for end-use, all in-house.

The metallurgical experts at Carpenter Additive offer over 130 years of material expertise to understand an application’s unique requirements, developing solutions and support for customers in the industrial markets.

Transportation

TransportationCarpenter Additive helps customers innovate the future of mobility to contribute to improvements in fuel efficiency, weight reduction, strength, and durability.

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.