Related Resources

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.

Material quality and consistency matter most; you get out what you put in. This is especially vital for mission-critical, never-fail scenarios. Carpenter Additive provides AM-specific powder designed to engineer out contamination with tight process control to ensure your material conforms to specifications. Our industry-leading manufacturing and processing facilities feature separate areas for each alloy category, reducing the potential for contamination from sizing, blending, recycling, multi-material machines and more, while our range of analytical techniques in our world-leading labs ensures contamination-free, statistical confidence through repeated sampling.

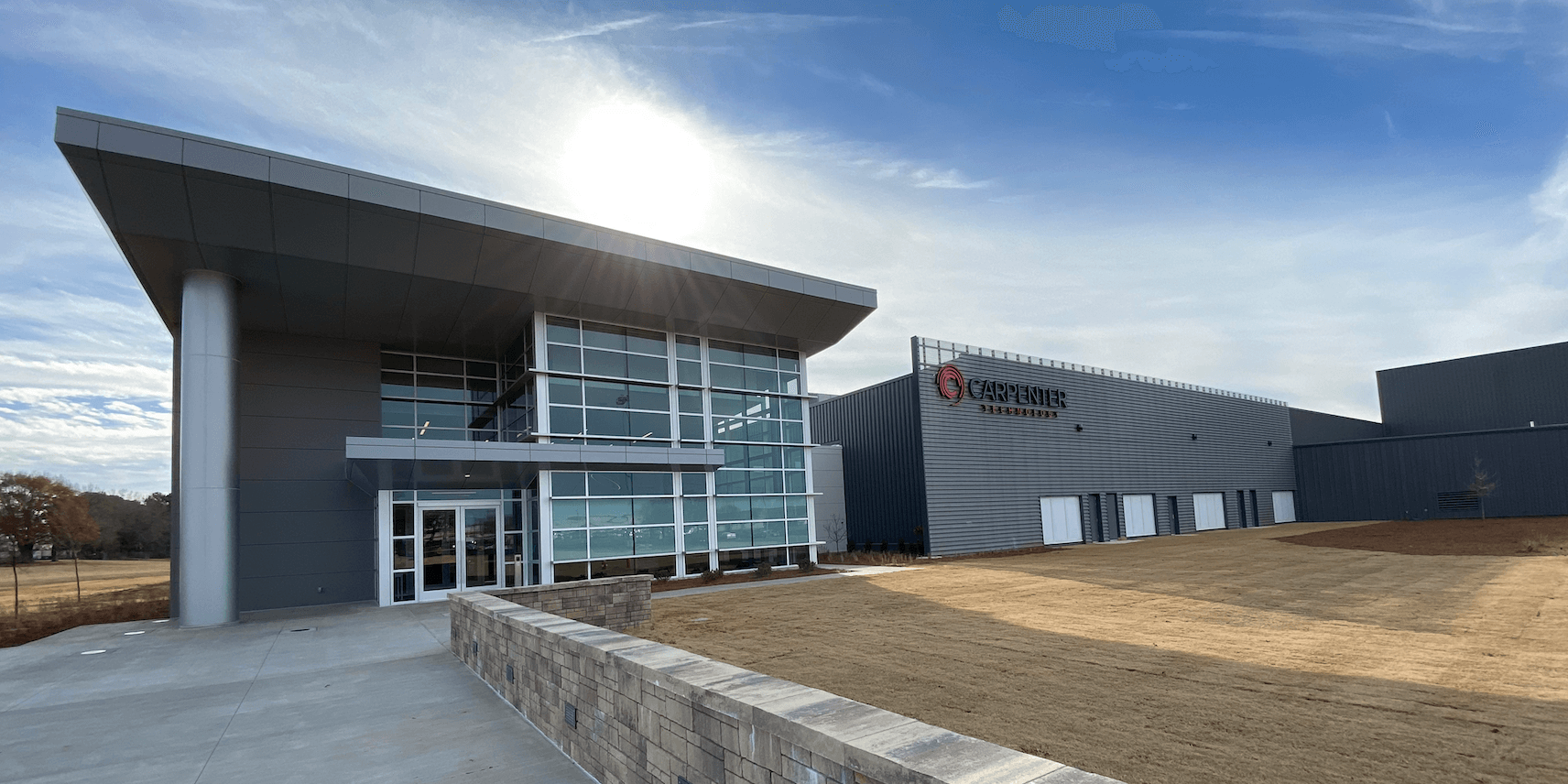

At Carpenter Additive, we're serious about AM. That's why we have multiple facilities dedicated to Additive Manufacturing.

From metal ingot, to atomization, to final built parts - we have facilities that support every stage of the AM journey, with data-driven solutions that optimize performance along the way. Trust in Carpenter Additive for your additive manufacturing production needs.

Browse our technical library of resources, including; white papers, product brochures, technical datasheets, webinars, and more.