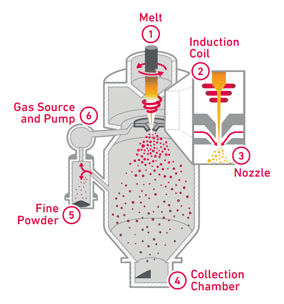

The most common method of metal powder production. An elemental feedstock is melted under an air or inert gas blanket, or under vacuum. The chamber is then backfilled with gas to force molten alloy through a nozzle where high-velocity air, N, He or Ar gas impinges onto the flowing melt and breaks it up. The powder is mostly spherical, with some asymmetric particles and satellites present. A satellite is when a smaller particle sticks to a larger one during solidification. Heat sizes range from 5kg to 3000kg. Size ranges from 0 to 500 micron. Yield within 20-150 micron range varies from 10 to 50% of the total. Mostly used for Ni, Co, and Fe alloys, also available for Ti and Al alloys.

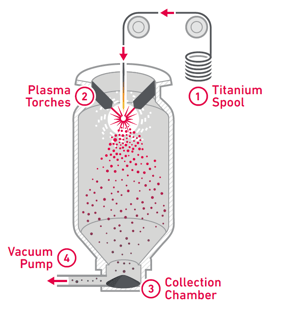

A prealloyed wire is heated with plasma torches and melts into droplets that cool rapidly into highly spherical powder, maintaining levels of interstitials such as O and N below ASTM standard levels. The main drawback of this process is the requirement for wire feedstock, an expensive material that offers little price advantage with scaling.

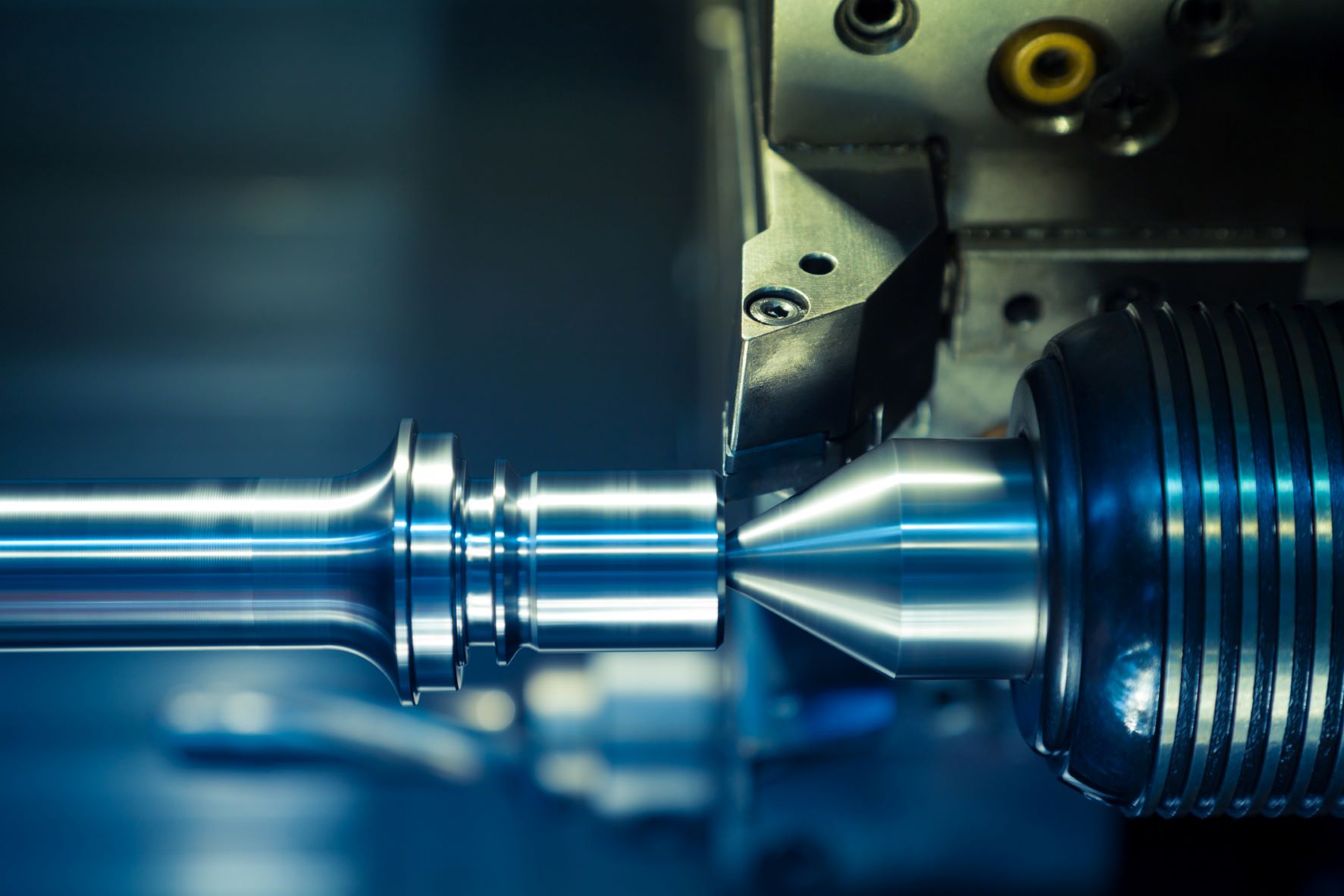

Works with all metal alloys but is most economic with reactive alloys like Ti. Feedstock, in the form of a bar, is rotated and melted by an induction coil. A film of molten metal flows downwards into a gas stream for atomization. Therefore, the material does not come in contact with either crucible or electrode during the process. Powder size is 0 to 500 micron and morphology is similar to gas atomized. The process is cheap, clean, good for small batches and produces small diameter powder.

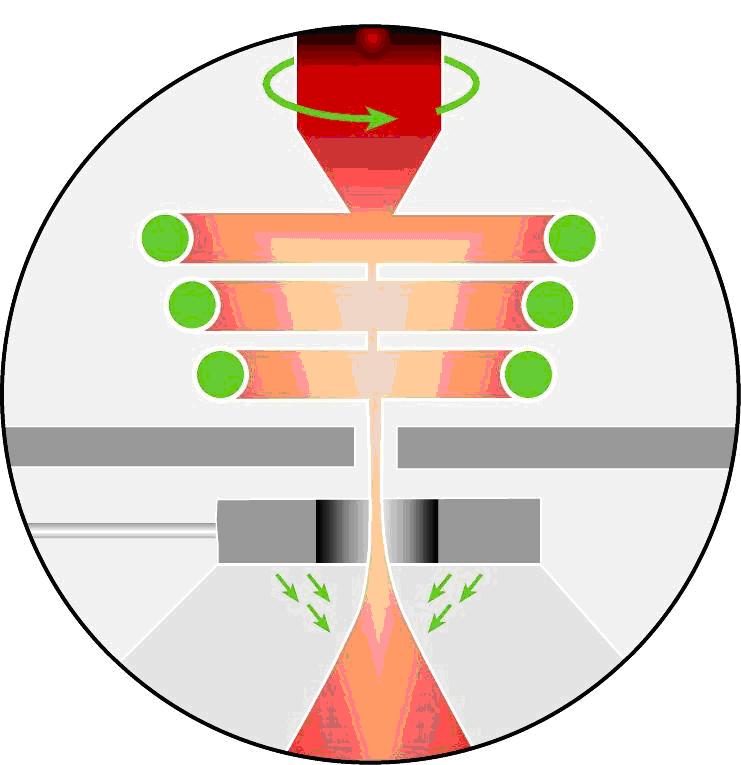

Carpenter Additive uses high energy plasma to produce highly spherical and dense AM metal powders. Carpenter Additive’s system uses plasma to transform agglomerated powders produced by spray drying or sintering techniques, or angular powders produced by conventional crushing methods, into spherical powder. The powder is gravity fed from the top and it is sprayed through the plasma by using various nozzle types depending on specific powder characteristics. Individual powder particles are completely melted and solidify in a spherical shape. Plasma treated powder is fully dense and highly spherical. Surface contamination is also significantly reduced through the vaporization of impurities.

At Carpenter Additive we have a high level of expertise in Additive Manufacturing (AM) and a long experience of working with leading companies within the aerospace, biomedical, and automotive industries. We utilize this knowledge and the capabilities of plasma technology to produce highly spherical and low contamination metal AM powders: